KANBAN systems and KANBAN principle

The highly flexible Kanban systems offered by us under the CPS®KANBAN service brand help you to make your warehouse and production effective and transparent. These Kanban systems are used predominantly by major industrial customers in the manufacture of their installations and products.

The most suitable solution for automatic replenishment is implemented, tailored to the particular item and to the individual work situation and requirements. Maximum availability of the right item in the right quantity in the right place at the right time in the production facility itself is always paramount.

The principle of the Kanban system, which originated in Japan, is simple: it is a rolling two-bin system that, in contrast to traditional supply methodologies, provides C-Parts "just-in-time" directly at the point of use. The system demonstrates great potential for adjustment if requirements change, maximum delivery and supply security at reduced inventory levels and minimal capital commitment.

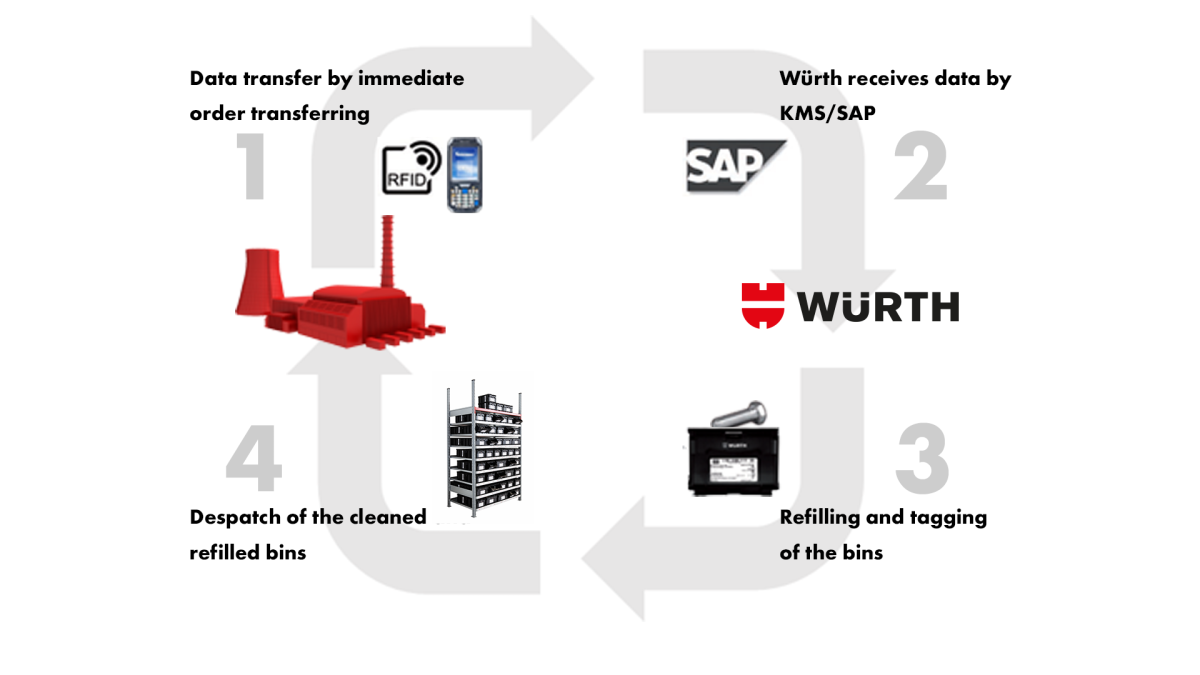

The flow of materials in Kanban systems is managed via two bins, each of which has a barcoded Kanban label or RFID tag, which specifies the customer, storage location, item, bin, batch and quantity in more detail.

Each bin movement is captured and documented, so that we can give you information about the status of your Kanban system at any time. This is enabled by Kanban management software developed in-house and our specialised European Kanban logistics centre in Bad Mergentheim, as well as the barcoded labels or RFID tags.

The data is used to schedule all C-Parts close to the point of use, to optimise stock levels and warehouse technology regularly and to update statistical data. As a customer, you can also find all of the data using the CPS®ONLINE information platform.

At the same time, a variety of special parts, parts designed as per drawings and specific commodity groups may be handled effectively. Our employees plan your specific, cost-optimised solution in consultation with all departments. We implement the system in cooperation with your company, and provide further support for product standardisation of your C-Parts.

- Maximum availability of your C-Parts during your manufacturing processes

- Transparent purchasing processes

- Reduced procurement costs

- Low capital commitment

- Greater flexibility within your value chain

- Constant monitoring of your status within the Kanban system using the Kanban management software developed in-house and the CPS®ONLINE information platform

- Just-in-time supply from the logistics centre

- A selection from a range of more than 1,400,000 industrial products

- Personal advice from employees with industry expertise